2.5-Axis Motion System

Project Overview

The purpose of this project is to design and build a 2.5 axis motion system that performs a certain task. In order to complete this project, various concepts like degree of freedoms and mechanisms will be utilized. The work volume of this project will be limited to a cube that is 2.5in x 2.5in x 2.5in. Other constraints for the project includes the fact that the system has to be small, easily disassembled (within 10 minutes by one person) and lightweight such that it can be carried in a backpack. Mechanical, electrical and computational components will be integrated to test the prototype.

Design considerations

Some of the design considerations are....

-

Build a 2.5 axis motion

-

Work volume is limited to a cube that is 2.5in x 2.5in x 2.5in.

-

Device will comprise of structure and motion elements (stepper, servo motors, pulleys, linear guides and belts.

-

Aluminum extrusion

-

3D printing/laser cutting will be required

After understanding the objective of this project, our team decided to brainstorm a few ideas based on what could be made given that it has to move in 2.5 axis motion. This decision came down to two designs, a 3D printer or an interactive game involving a slingshot. Because the group wanted to design something that was more interactive and less common, the slingshot idea was chosen.

The first degree of freedom will involve a belt that controls the motion along the x-axis, the second degree of freedom is a linear drive will control the angle of rotation of the slingshot and lastly, a solenoid will be used to control the y-axis motion in terms of the .5 degree of freedom.

After deciding what to design, a brief list of materials was made

Materials:

-

5 aluminum extrusions

-

1 acrylic sheet (3x3 in)

-

solenoid

-

1 belt

-

joystick

-

Rubber band

-

Velcro tape

-

1 Arduino

-

2 servo motors

-

rod for linear drive

Sketch

Below are initial sketches of the slingshot design. All of the drawings shown below were modified later on in the process to improve the final product. The two biggest changes in the designs would be the size of all the parts. The thickness of the top casing had to increase because it has to contain the solenoid. When the box was designed, only the diameter of the rod of the linear drive was taken into account but not the diameter of the shaftAs a result, the width of the bottom casing also had to change. For the correct dimensions of all the parts, a CAD drawing is provided below for the finalized dimensions.

The images shown below are CAD drawings on PTC Creo of the 3D printed components used to construct this project. These files include the box which is connected to the linear drive and controls the angle of the rubber band. The Bottom Casing will be connected with the belt which will move in the horizontal motion. The Top Casing will be used to house the solenoid to control the 0.5 degree of freedom and will be it will be the component that releases the rubber band. The last component shown in the images below is the motor casing, this will be used to house the motor so that it can slide along the aluminum extrusions bars. The slider for the 8020 profile was given as an .stl file.

Coding the Arduino

In this section, the images shown are the codes that were used for this project.

When buttonstate is equal to zero, it will supply power and the solenoid will go down. However, due to the else statement, it will not supply power and the solenoid will not go down (remain at the same position).

Used a value that is greater than the normal value because it makes the joystick and the button less sensitive when controlling. In other words, it will cause a delay.

step_fwd and step_bwd function used to control the motor for the belt.

Part 2 is the beginning of the control of the second motor which is used to command the linear drive. The concepts for the codes used for the two motors are the same.

Circuit Modelling

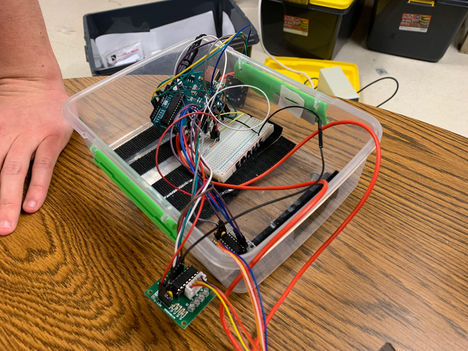

After uploading the code into the arduino, the group began to construct the circuitry based on where to insert the wires into each ports while corresponding to the code. In the video, a larger motor was used because the group thought there won't be enough power to move the 3D printed components horizontally. It can be seen from the video that after everything was wired together, the rotation of the motor was checked to ensure that the code works and that when the joystick is pressed, the solenoid will go down (releases the rubber band).

Circuit Testing

However, towards the end of the project, the code was modified such that it works with the smaller motors. As a result, the final design performed as expected with the two smaller motors.

From the image on the left, power is supplied the arduino and the arduino is connected to two other circuit boards. Each of the circuit board controls one of the motors (one for the belt and one for the linear drive).

This arduino will supply 5V. However, the motor and the solenoid need 12V. Therefore, a transistor is used on a breadboard to allow a 12V solenoid to be able to be controlled using an arduino.

Lastly, the arduino is connected to a joystick which is used to control the angle and horizontal motion of the design.

Constructing the Slingshot

While constructing the circuitry and writing the code for this mechanism, some of the parts were 3D printed. These parts include the motor casing, top and bottom casing, box and the slider. Images of these components being 3D printed are shown below. Some of these dimensions were modified throughout the project to ensure that the slingshot would function better. For example, the front pin for the top casing was added to the part. This is because it will increase the stretched length of the rubber band, allowing the object to be shot at a further length which makes the game more enjoyable.

After the parts were 3D printed, things were connected together by using glue and screws. For example, in the image on the right, the rod that was used to control the angle of the slingshot was connected by using a screw while the top and bottom casing were connected together by a thin fabric.

The aluminum extrusion bars were cut in EPIC to the sizes according to the dimensions. However, the whole group realized that the game would be more challenging if the motion was not limited by 2.5 inches. Therefore, the group made a decision to go beyond this restriction and made a frame that was larger than the specification. The method that these bars were connected together were threading 1/4 20 screws into the aluminum bars and drilling holes into the perpendicular bar so the allen wrench can be inserted to lock the screw in place.

Each of the sliders were attached by glue to the motors, and bottom casing so it can slide smoothly within the aluminum extrusion bars. The belt was cut after the length has been determined so that the bottom casing slides smoothly along the bar. Afterwards, velcro was taped onto an acrylic sheet and then painted over to make a target for the game. A pin was wrapped around with velcro tape so that it will be stuck to the target.

After combining all the components together, the slider for the motor that controls the linear drive was removed because it would get stuck between the aluminum bars. Therefore, an acrylic sheet was placed on top to solve this issue. This allowed the motor to slide with the slingshot. Holes were drilled so that screws and nuts could be attached to the aluminum extrusion bars.

Final Product

The Final Product of the Slingshot is shown below. This include both images of the slingshot itself, the circuitry, and a video of how to play the game. The video shown with the images below demonstrates that the objective of the product has been met. The slingshot is able to move in the horizontal motion, rotate freely, and is able to control the solenoid by a joystick.

Conclusion

To conclude, although not all of the specifications for the project was met, the slingshot that was designed was able to move in 2.5 degree of motions. This includes the horizontal motion, the motion from the linear drive and the motion from the solenoid. The product that was designed is easily assembled and lightweight.

The 2.5 Axis Motion System was very insightful especially in terms of the design process. All of the components had to be design to such precision because this project is very detailed. Even though most of the specifications were met, there were still some improvements that could be made to this project. This includes making the design more appealing to the users instead of only having objects in rectangular objects. Another improvement would be to add belts to both the bottom casing the the motor that is parallel to it so that it can move at the same time, this will prevent the usage of the acrylic sheet because the slider will not be stuck in the aluminum bar. Lastly, improvements could be made to the rubber band to increase the distance of the projectile motion.

After completing this project, I felt more comfortable with various machines in EPIC. I learnt and understood more about how different parts can be manufactured and modified. I also understood more functions in the arduino program, especially functions for the motors and the joystick.